BLUF, magnet is required and not an option!

Just in case anyone wants to know why this is…

Our ATC’s are all high quality metalworking 4-pole 800Hz motors with Ceramic bearings. ATC’s are our premium product and thus we wanted to have the best, most requested, features.

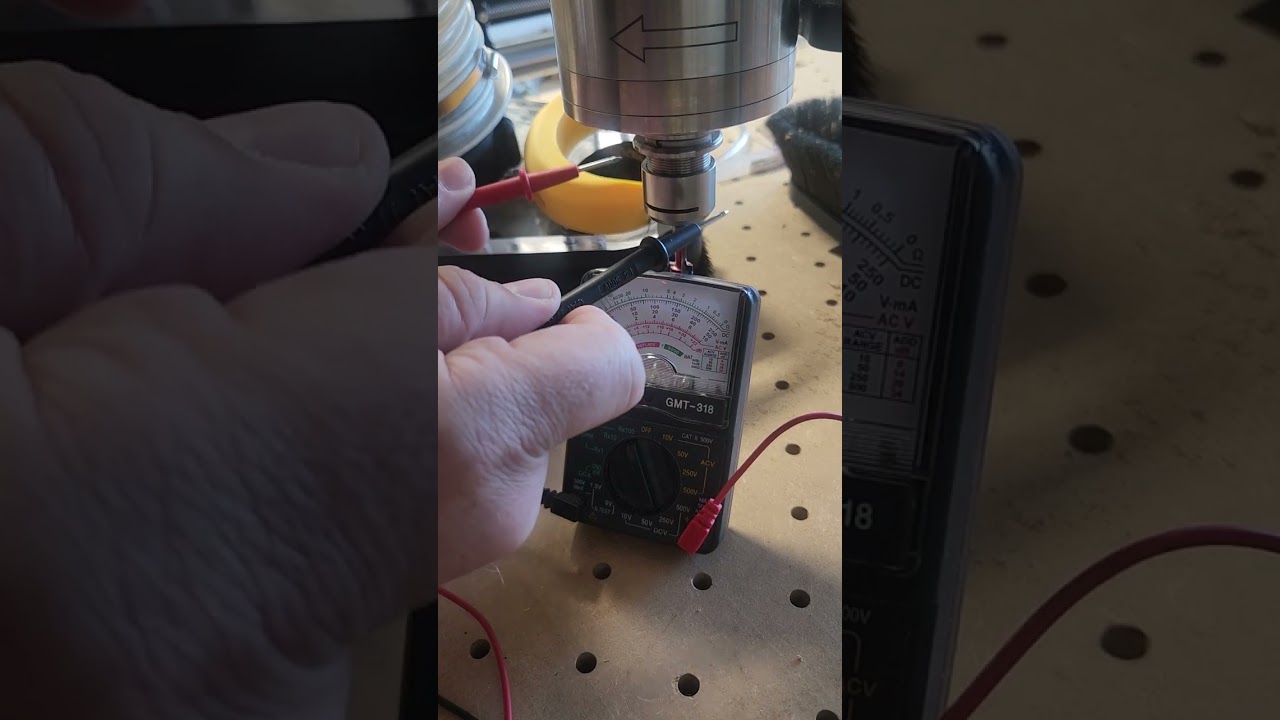

Ceramic bearings means there’s no electrical connectivity between the shaft and the spindle’s body. The spindle’s body is grounded via pin 4, but that grounding is not transferred to the shaft.

Will this have an effect on atc tool changes?

It’s only has an effect on probing. If using a tool setter, no effect as there is no magnet involved. If using a probe as a setter though, it will.

Just ordered the toolsetter from the store…as you might of guessed i was using the probe approach. You guys are forcing me to clean up my act.

They are 2 seperate components and have different logics associated.

The probe is for getting an initial zero and is commonly a piece of aluminum with 2 wires, one to the block, the other to be attached to the bit/nut via magnet or gator clip.

The setter is commonly a switch of some kind that makes the necessary electrical connection and measures the offset, changing the z height with a new bit when you remove the old one. The ATCs ISO20 holders will lock the bits into place. With that in mind, the setter will make the task of getting those offsets faster & easier but won’t be used frequently (unless you choose to). I have my tool setter about 1/8" below the work surface, and it’s out of the way, but still usable.

Probes can be used as probes or setters (if you want to change the hardware connection or software allocation)

Tool Setters are for measuring offsets, and while can still be used as probes, it’s not the best tool for the job (like a screwdriver in place of a hammer)

Yep, im up on all that. I use the aluminum block for probing for location of zero, but i was using another aluminum puck for tool changes and without that electrical connection with the spindle…well bobs your uncle.

Just curious about what makes the standard PwnCNC 80mm water cooled spindle incompatible with the ATC?

Alot, but as it pertains to the subject, its that the ceramic bearings are not conductive.

Other than ceramic bearings, what makes the standard spindle incompatible with the ATC?

The ceramic bearings isn’t something that makes it incompatible as we sell ceramic bearings for the traditional spindle as well, but the difference is comparing semi truck to a honda civic for hauling.

It just can’t do it.

Theres no pneumatic chamber for tool changes on the traditonal spindle which isn’t necessary since the traditional motor doesn’t have the lower assembly that detaches. The entire mechanics of the inner workings are completely different, while they may perform the same task (making man glitter) the engine components are missing/different.

That’s exactly what I was wanting to know. Thanks, Chris!

With the ATC, it’s beneficial to use a dedicated 3D touch probe, which doesn’t require spindle shaft conductivity and can be prepared with a known length ahead of time. This makes it easy to then find edges AND calculate tool offsets on automatic (or manual) changes.

I think a really good analogy is the difference between regular 2-wheel drive vehicles and a 4-wheel drive.

There’s extra components for that pneumatic functionality as Chris mentioned.

Traditional spindles have their drive-shaft built with the ER collet functionalyt on the end. For these ATC spindles, it has a ISO20 tool holder style draw bar/clamping system on the end of it’s drive-shaft. The pneumatics are used to disengage the spring loaded draw-bar clamp to release the tool holder.

The electrical part of ATC’s and traditional spindles are exactly the same though. Both are simply copper wire wrapped around a shaft spun by current inside of a magnetic field. The pneumatic controlled clamping draw-bar is the key differentiator.