Have you ever wondered what the inside of ab ATC motor looks like?

Our ATC motors offer serious power for your hobby CNC machine! They’re all capable of carving wood, acrylic, foam, aluminum, and even steel. Since they’re 4-pole motors, they have higher torque at lower speeds unlike standard woodworking motors. They also have high-quality ceramic bearings and come standard with our custom kool connectors.

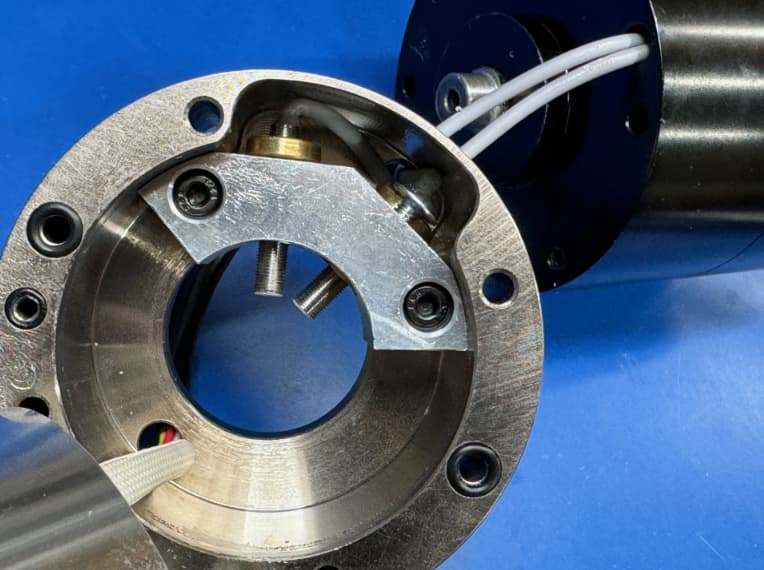

There are body of these ATC motors are divided into three parts.

The motor’s sensors are simple proximity sensors used to detect the positioning of the piston sticking out of the black part and the draw-bar sticking out of the larger silver part.

The draw-par is this piece here when depressed, it opens the clamp holding the ISO20 tool holder. It’s spring activated so when pressure is removed, the drawbar returns to it’s naturally clamped position.

The main functionality of the black top part of the motor is to hold the piston assembly. When pressurized, it presses down on the draw-bar unlocking the ISO20 tool holder. When pressure is removed, the spring loaded draw-bar returns to it’s natural position pushing the draw-bar back up into the black piston assembly.

Various channels around the diameter of the black shaft allow for air and coolant to flow down and through the entire motor assembly. Rubber gaskets are used at joints to prevent any leakage of coolant or air.

Wire channels are also around the perimeter passing the main spindle motor’s power and proximity sensors to come out the top of the motor.