I know I read this somewhere but haven’t been able to find it. With the ATC installed on my Elite Foreman, what will my max X cutting width be? I have the QCW, if that matters.

There are too many variables to answer this question accurately.

Where are your tools located, How many are there, and Which tool holder are you utilizing are 3 of the variables.

the flush, short, and tall holders are all 60x60mm square. the QCW mount is more elongated and we haven’t established how many can fit there on the Foreman. I can fit 20.5 which might count as 21 of the tall holders. I’ll report my findings once I am set up.

If you align the tools on along the x axis, you won’t lose any X, but you’ll lose tiling capablitliy (unless you tile with a flip instead of a pass thru)… if you align them along the Y, you will lose some, but it also depends on which dust boot you’ll use dictating how many tools you can have along Y (additional spacing will be needed for v10) I’ve measured mine to be 5 or 6. Again, I’ll report my findings soon. I don’t have a QCW, I have a home made table for my Foreman.

Jeff and I are the only ones with a Foreman in the company to my knowledge, and neither of us have a QCW.

I will be aligning them along the Y, as far to the left as possible. I have the v2 boot. How do we know which style holders we need?

I find it incredibly unlikely that the v2 will be ATC compatible (try and fit your 80mm spindle through it, and you’ll see why I feel that way). V3 shows potential, and again that’s on my test list, and V9 / V10 are already proven.

Any of them will require some form of modification to your wasteboard. The tall will bring it up the highest, and I anticipate that is what will work for me as the foreman has several challenges that aren’t associated with the journeyman and woodworker since the foreman has a taller stature.

Here is the information from the tool rack listing.

No ATC setup is complete without tool racks. We’re continuing to design different styles of tool racks so you can always get the one that fits your setup perfectly. They’re designed to hold our ISO20 tool holders available separately. If you just bought our ATC System, (4) Flush mount tool holders are included. It is unwise to mix and match the tool holder styles so please purchase accordingly.

Tall racks require you to drill a 1 inch hole for the bit to stick into your spoil board. The end of the ISO20’s collet nut sits roughly 1" above the spoil board. This type of holder is perfect for spindle mounted dust boots. The tall stance prevents the brush material of your boot from being smashed into the spoil board during tool changes.

Short racks require a similar drill-hole to our Tall Rack. The end of the ISO20 collet nut tool holder will sit just atop your spoil board. This type of holder is recommended for no dust boots.

Flush racks do require the same 1-inch hole as the tall but are mounted as low as possible. These provide the perfect alignment between tool holders for your ATC motor to drop down and grab the tool without interfering with the tool holder immediately next to it.

QCW racks are what we installed onto our Woodworker QCW table. This might not be best for everyone.

We are always coming up with new ideas for how to position our tool racks. If you have an idea for the perfect tool-rack on your setup… please reach out to us via support@pwncnc.com and we’re happy to develop and make it available.

Marty,

I did some deeper thinking, and think the qcw mounts will be best for you.

In the atc setup video Daniel posted a month or 2 ago, his x was 0 and the holders were the lowest possible which will decrease the minimum height a Z independent boot will be. If you for example got a tall holder, the minimum point where you can have your bracket set to is increased.

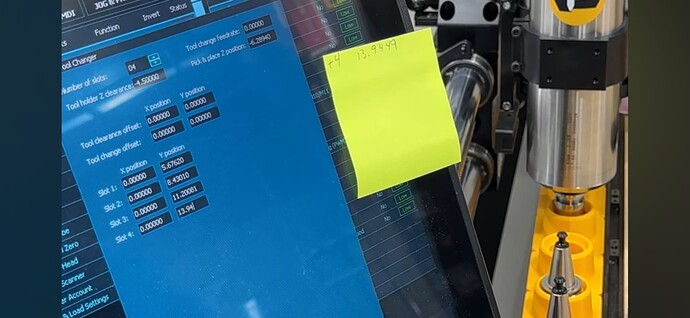

The wild card is the foreman on a qcw which noone in the company has, and if you can jog to x0/48 with that slat removed we can get a better idea

Is it possible to mount a tall tool rack to the table below the QCW table so the use of V9 boot is more advantageous? Maybe not install the most left piece of wasteboard which opens the QCW table to the table below.

Yes absolutely. One of our ATC buyers is working on a very cool modification of his custom bed. A box/tray that has 3-piece drop-in set of racks. It’s removable so he can put a “blank” in it’s place if he ever needs full capacity of his bed. but most times it’ll have the 3-rack insert.

The only limitation is how far down the atc motor can reach. We’re going to be encouraging everyone to share their tool-rack designs to help everyone get an idea for their own designs.

We’ll monitor closely and if there’s someplace we can help by either mass-producing something… maybe metal, plastic, whatever… we may bring those to market so everyone benefits (with permission, of course, or even a licensing deal if it’s particularly good).