I am posting this with Images over time. I will start with the ordering process and disassembly as for me the ordering process was not straight forward. I get the bug and just order without full research. The Pwncnc website is not the best with some information missing or not updated. Sorry Daniel.

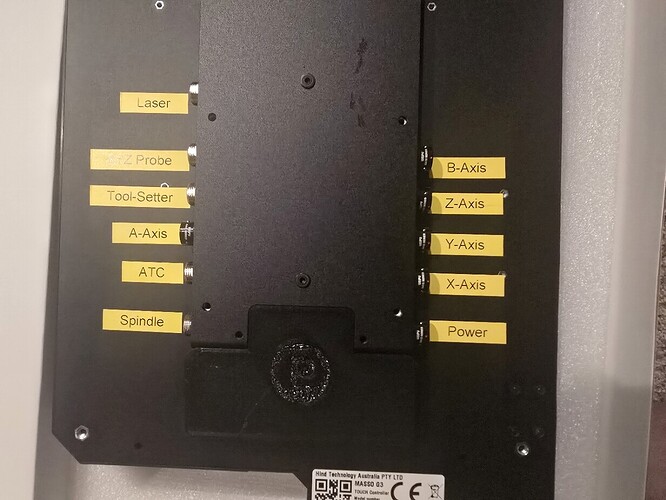

1. There are 2 Masso touch conversion kits you need the advanced to use an ATC. The Advanced Masso Touch comes with a Pwncnc rear plate with all of the connectors preinstalled and marked. Looks clean to me. I don’t see any image og the back of the basic kit. There is no VESA mount offered you ate on your own. Realize there will be a few cables coming into the Masso Touch so plan on a freeway of wiring that needs to be managed. The tool probe and touch probe is prewired in the advanced version, as is an extra 4th axis motor, (turning or maybe liftable dust hood for the ATC) I don’t have a need but it is there.

2.Touch plate and tool setter is extra and is not included with any kit.

3. The VFD enclosure needs to be the V5 for the ATC and separate brake. My older spindle was not V5. You can send in your old VFD and have it converted, its not cheap. The difference is EMI shielding better plug. manual / auto switch that can be moved to the Masso Touch (additional cost for the mount), brake port, and sensor cable port to properly use the manual VFD tool change function. This also means the VFD has to be reprogramed or setup for this ATC sensor to work. Not sure I included everything here. This is specifically for the ATC. My older VFD would have worked with the Masso Conversion only. So yes I ordered a new VFD V5 because I can’t wait.

4. The newer Air controller has only one pressure regulator not shown on the web site.

Disassembly, you should not need special instructions here. You put it together just take it apart

So first thing is strip the machine of motors cables and cable chains. Everything,

I removed all of the plastic covers on the Y axis frames. I removed the small PCB that lights up the carbide logo and has plus for the Shapeoko tool setter and touch probe. I also removed the Gantry light as it just peels off. Pawncnc has a replacement with cord for the masso (it is not wired in on the MassoTouch but comes with the connector).

When you remove the motors you do not have to loosen the connector just remove the mounting screws an wiggle out the motor it will separate from the urethane cushion. You can then separate the connector off of the machine. Remember to loosen the diagonal screw first than the smaller set screw, otherwise the small set screw will be too tight to remove.

I so took the time to disassemble the machine to make several mods and to clean and lube the linear rail tracks and bearing blocks. The blocks do not drop bearings. Just do not remove the ball screw nuts. I use a lightweight grease as oil is hard to apply when the machine is assembled

Notes

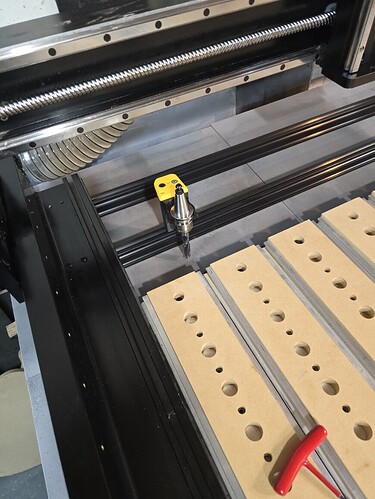

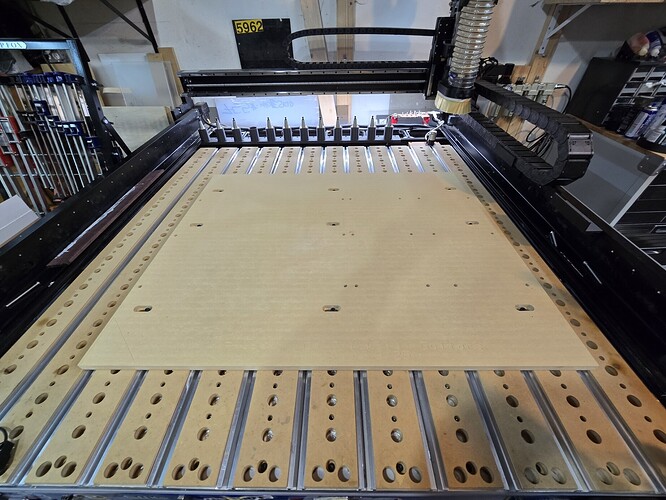

The machine Frame is not the Ideal candidate for an ATC, you will have to settle for some sort of offset of the bed in my case a 4x4. I am not doing sheet goods so the loss of work space VS not having to change tools by hand is a good compromise. Shapeoko’s Frane z heigh has only 6.1 inches of travel. So tool size is an issue and some sort of modification is necessary. Most people just remove one slat and a t track section. The onefinity would and is a better candidate But I do not own one. Using a vertical tool holder is not ideal and I went with the side mount holders.