Hi. Bought an 80mm 1.5kw air cooled spindle for my Onefinity journey man pro.

When resurfacing the spoil board with 1/2 shank 2.0” tool the bit slips.

Suggestions?

How are you installing the collet into the nuts prior to installing the bit. A bit slipping inside a ER-20 collet is virtually impossible.

The collets DO NOT work like a router collet. You have to install the collet into the nut properly, thread it onto the shaft, then install the bit and tighten. If done correctly the holding force is strong enough to surface steel in milling machines without slipping.

I have an 80mm 2.2kw spindle which uses ER20 collets. You may not be seating the collet tightly because of dust and debris in the collet, collet taper or in the collet clamping nut. Clean the collet clamping nut, the collet taper and the collet after every single use. I use a strong vacuum hose but an airline or a brush can be used.

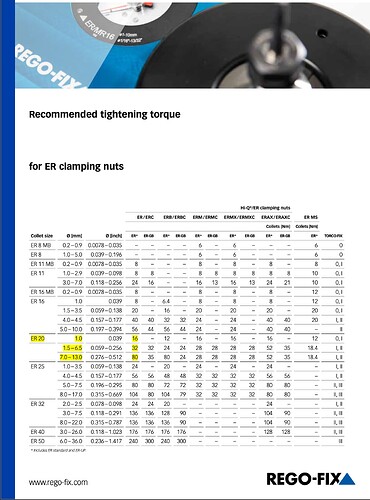

There may be a case where the collet nut is not being torqued sufficiently. I use REGO-FIX Ultra precision collets and I clamp them using a torque wrench and a REGO-FIX castellated clamping nut. REGO-FIX designed the original ER collet system in 1972 and they recommend torque settings based on ER20 collet sizes thus:

Collet sizes with recommended torque settings:

1mm ~ 16N-m

1.5 to 6.5mm ~ 32N-m

7 to 13mm ~ 80N-m

REGO_FIX torque settings table for ER Collets

A very short video clip concerning ER collet use.

Hi Clinton

I will try again.

It slipped twice this time I’ll video.

Yes collet in nut first. Then onto spindle. Then insert bit. Tighten!!!

Again I’ll try and video.

Question

Is the spindle direct drive? Belt?

Could something slip on the inside?

Ways to adjust?

Thanks!

Have you put calipers on your bit to ensure the shank is the proper size?

Yes spot on. .50.

Thanks!

Yes. I did this as you suggested. I seated the collet into the bunt bfirst. Then screwed the nut on a little then inserted the bit. Band tightened. Will try again today…

Question: is the spindle direcrtdrive?

Some spindles have internal belts to transfer power/torque.

If not direct drive are there internal adjustments?