I’m setting up my PwnCNC ATC on a Onefinity woodworker and I’m trying to decide what the best spindle location in the z-mount will be for me. I appreciate feedback from any experienced CNC users.

(1) Bit deflection

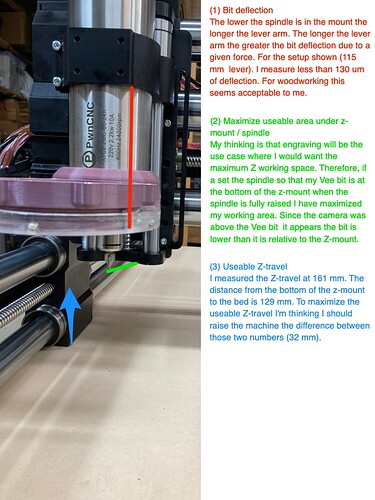

The lower the spindle is in the mount the longer the lever arm. The longer the lever arm the greater the bit deflection due to a given force. For the setup shown (115 mm lever). I measure less than 130 um of deflection. For woodworking this seems acceptable to me.

(2) Maximize useable area under z-mount / spindle

My thinking is that engraving will be the use case where I would want the maximum Z working space. Therefore, if a set the spindle so that my Vee bit is at the bottom of the z-mount when the spindle is fully raised I have maximized my working area. Since the camera was above the Vee bit it appears the bit is lower than it is relative to the Z-mount.

(3) Useable Z-travel

I measured the Z-travel at 161 mm. The distance from the bottom of the z-mount to the bed is 129 mm. To maximize the useable Z-travel I’m thinking I should raise the machine the difference between those two numbers (32 mm).