I’m extremely sad to report that as Nick and I were following the assembly manual I wrote this week on how to assemble the Dominator we ran into a sizing snag with the production linear rails.

Not to worry… we have a plan and while it won’t delay the initial orders going out in early July, it will delay orders we wanted to go out in mid-July. This second batch of orders could be delayed by as much as 2-3 weeks, but this will depend on how quickly our vendor gets us the correct length rails.

Good news is we caught the problem soon enough and with fast shipping we’re able to minimize the delay.

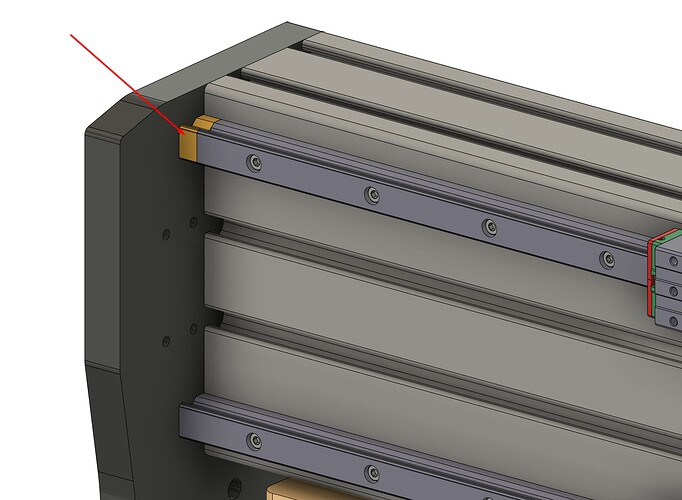

Root Problem: The X rails are 2mm too long! This is my mistake during the design phase and I am owning up to it by paying extra to have the correct length rails shipped as fast as possible.

Short-term Solution: We have a small batch of rails from our prototyping order in December that will work IF they are very carefully aligned side-to-side so the bearing blocks don’t go off either end. I’m going to design a special 3d printed jig which will allow these rails to be aligned perfectly by adding the exact size gap between the linear rail and the left end-plate during assembly. It will not affect the operation of the machine nor will it reduce X capacity.

Long-term Solution: My initial goal was to have both the Y and X linear rails the same length so we could have fewer SKU’s to stock. I’ve recalculated the ideal rail length for this goal and I’m placing an order right now for the correct length rails. By my estimates they should arrive in the next 3-4 weeks from today.

Thank you all for your support of PwnCNC as we go through our trials and tribulations to launch the Dominator CNC.

Side Note: Some great news is the assembly manual is going to be awesome! Nick wrote lots of notes on my first draft as we were rebuilding the Dominator in our facility. I’m updating the manual this weekend and we’ll continue to enhance it next week. The plan is to include a full-color printed manual with each machine we ship.